Who Else Wants Info About How To Develop A Haccp Plan

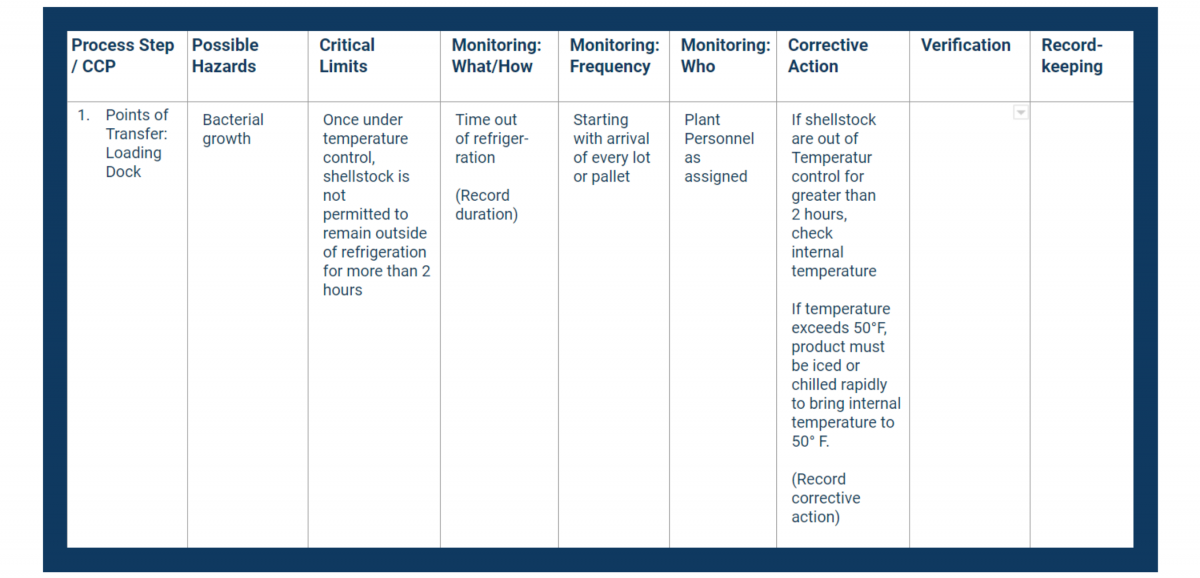

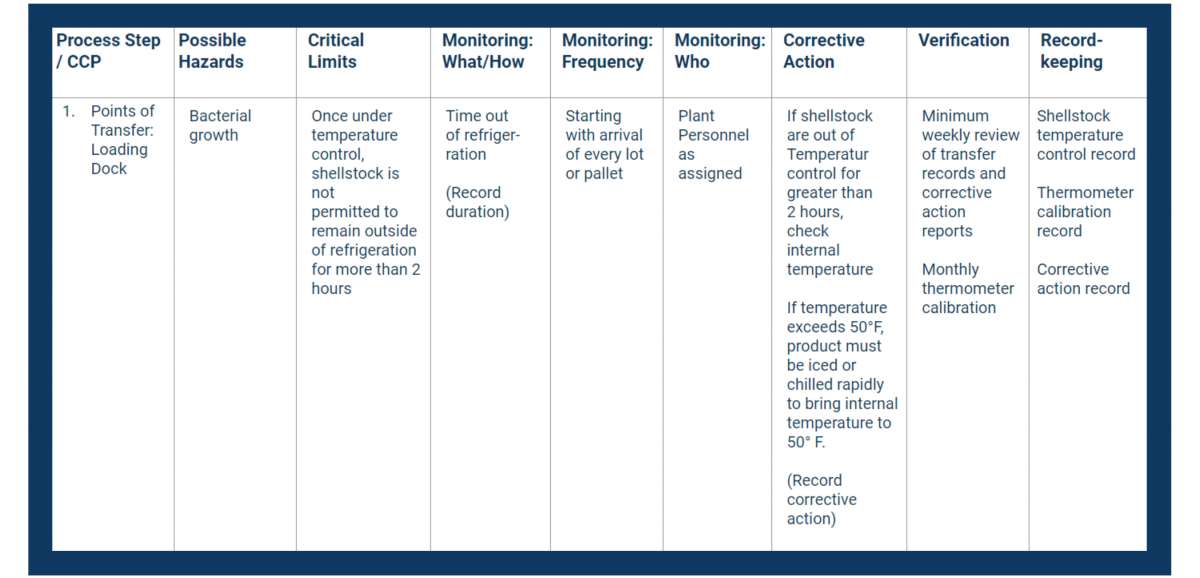

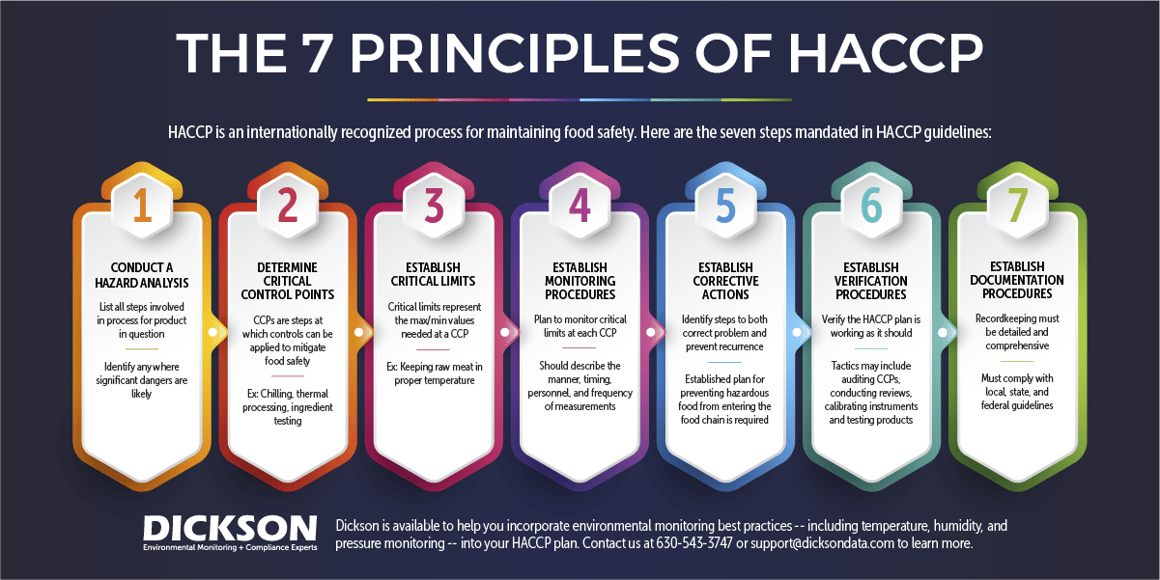

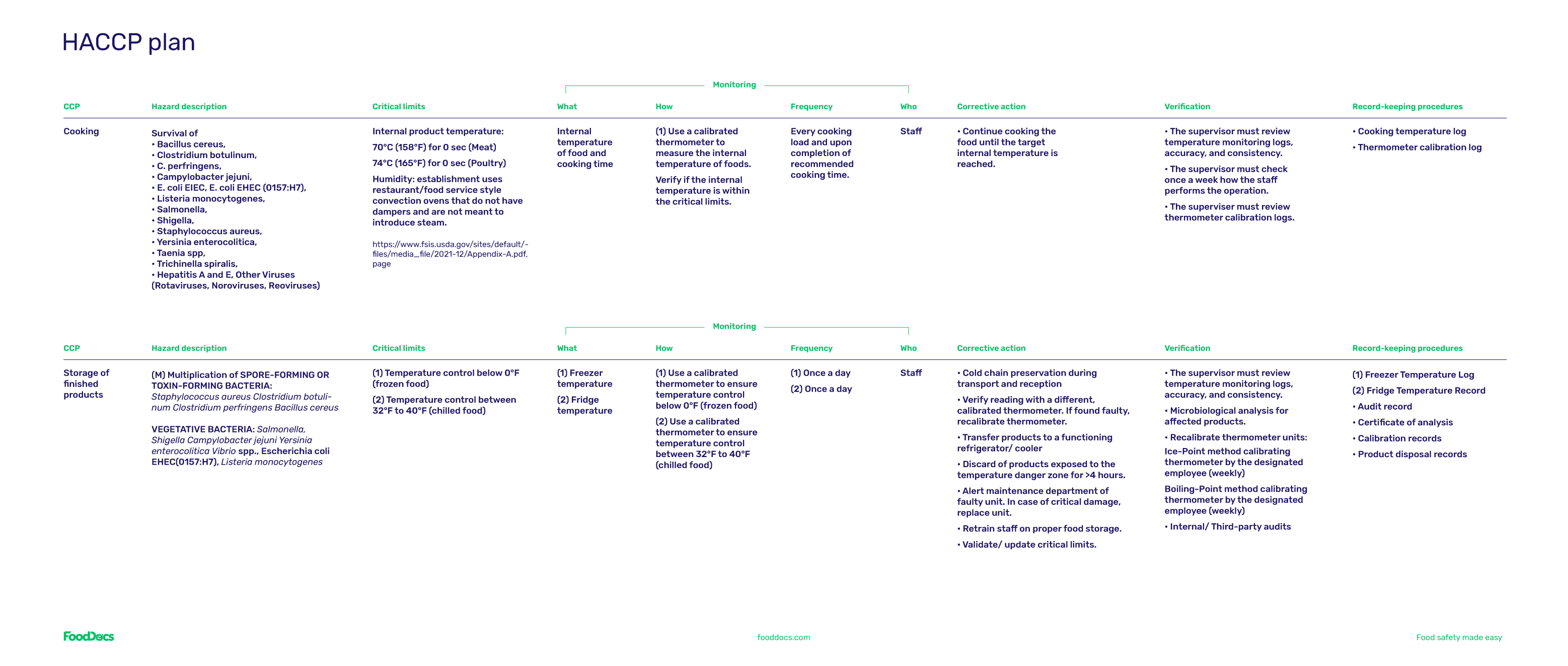

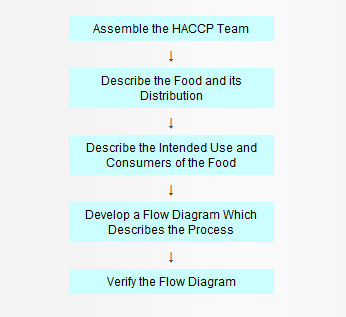

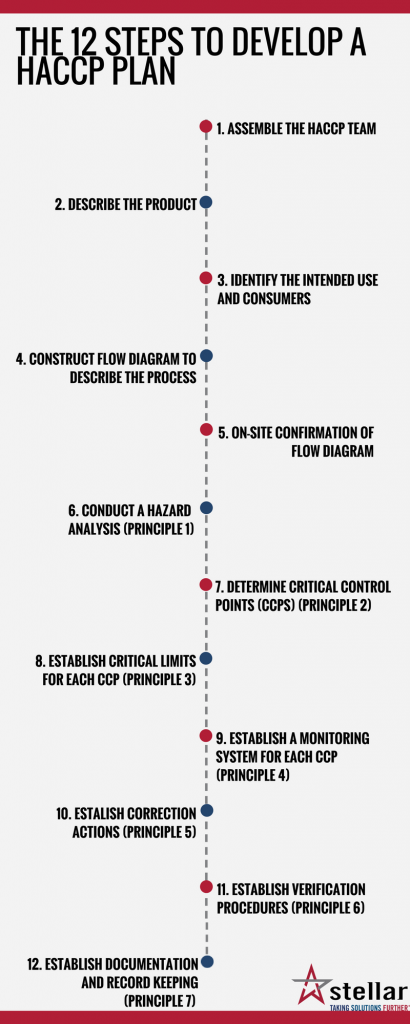

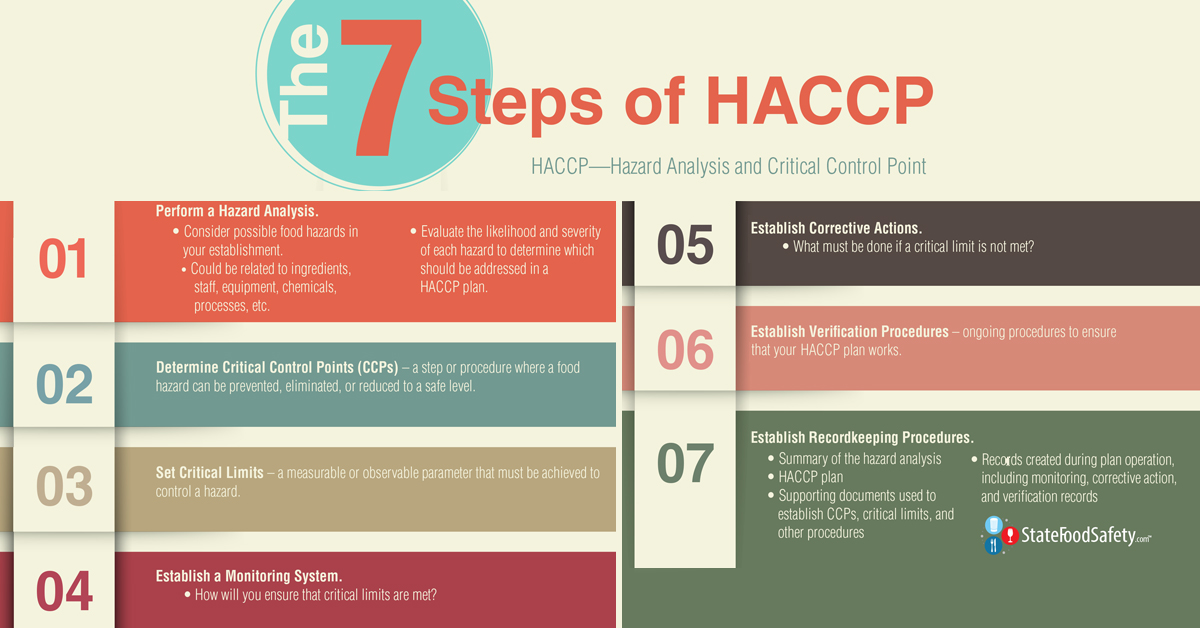

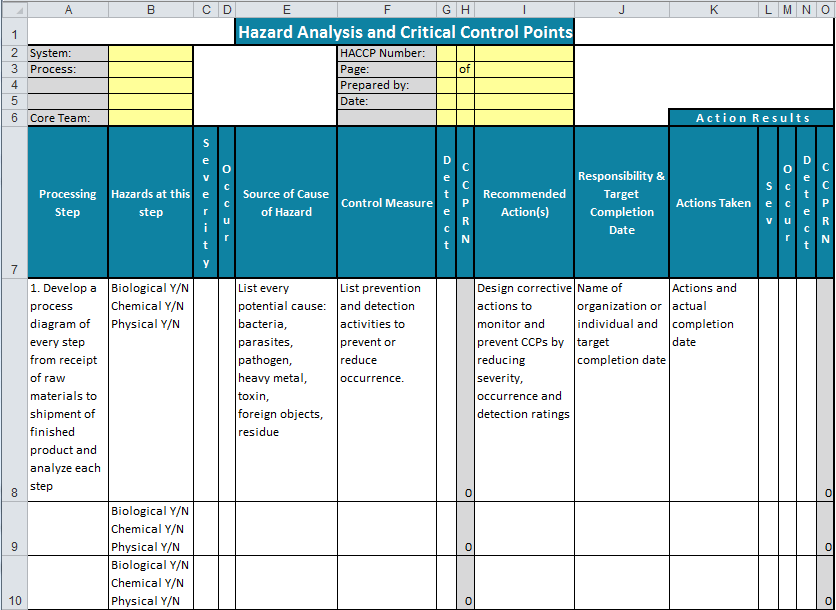

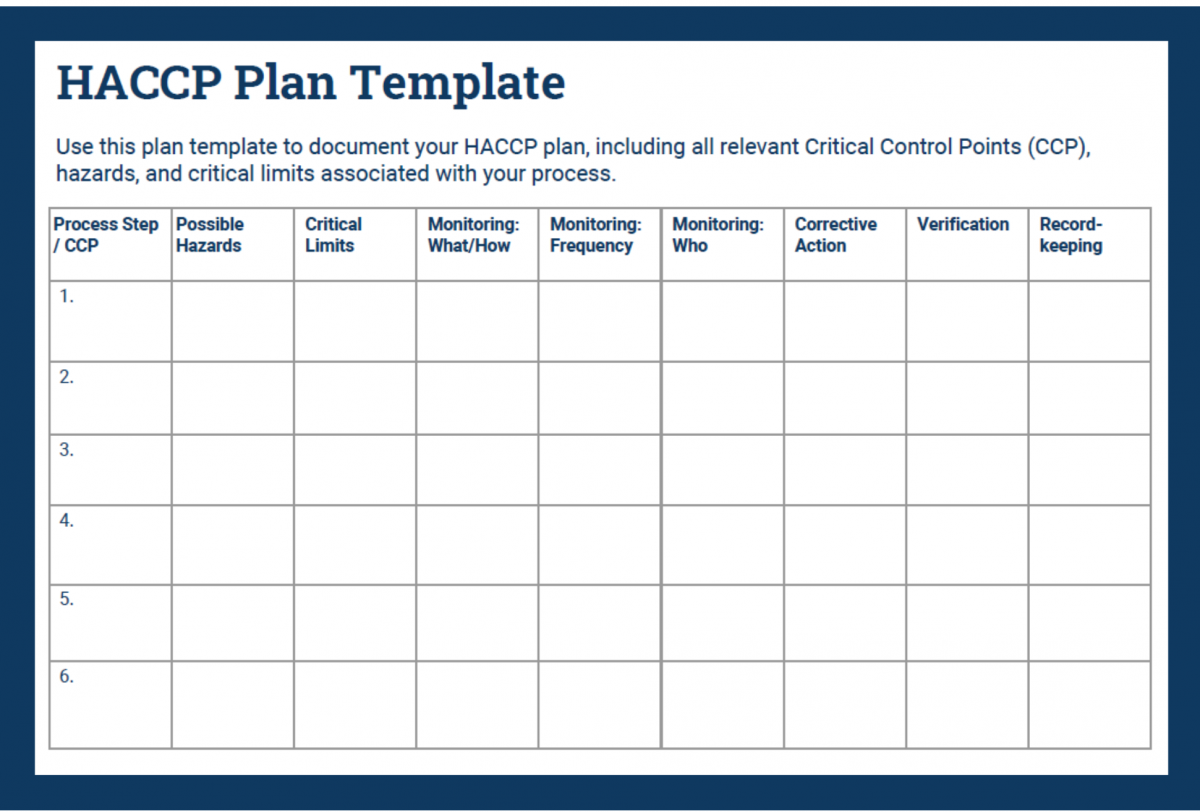

Developing a haccp plan consists of 12 tasks with seven principles, which are further explained below.

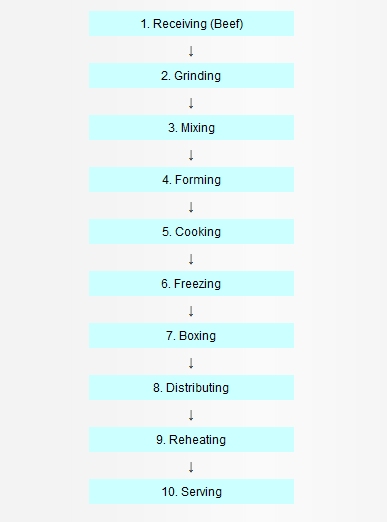

How to develop a haccp plan. The haccp plan keeps your food safe from biological, chemical and physical food safety hazards. To produce a haccp plan for your business follow these 10 steps: To make a plan you must:

How to develop a haccp plan. Study the models as they develop their haccp plans. There are twelve tasks required to develop a haccp plan and these are designed to ensure that the seven principles are applied correctly.

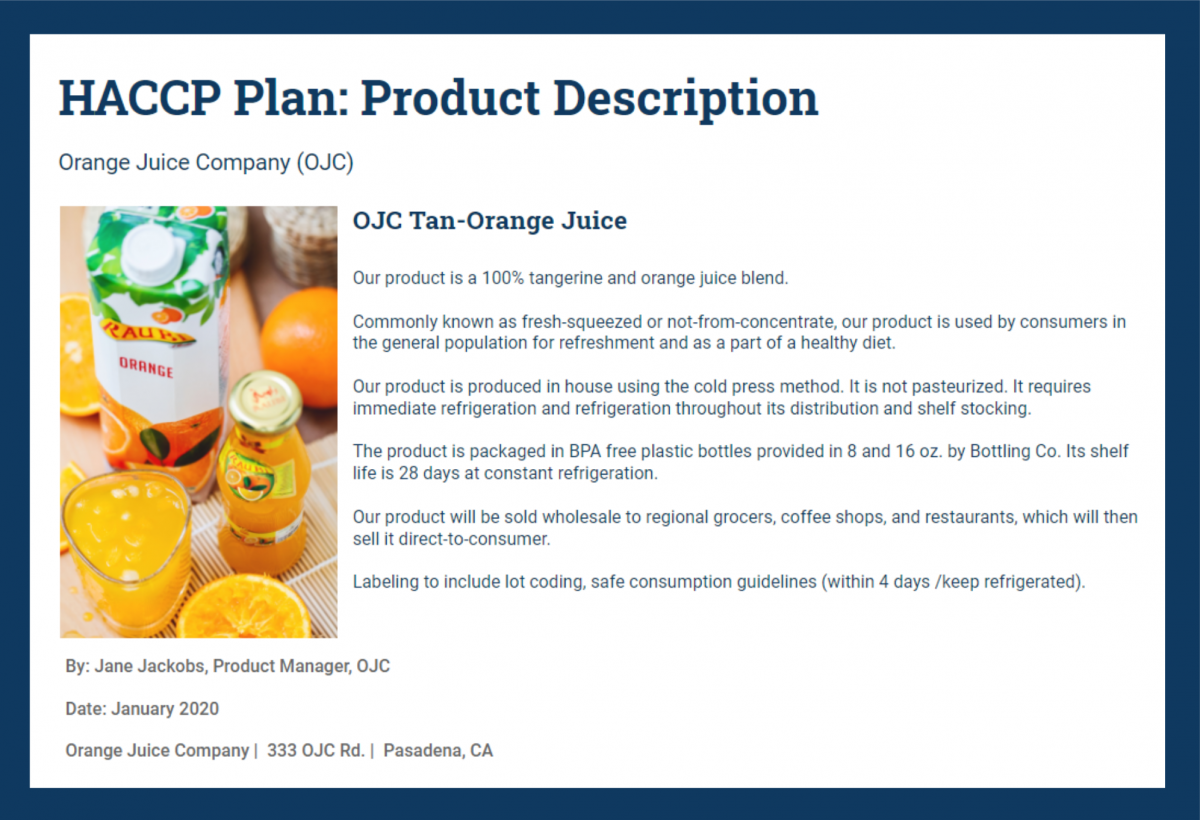

Then the method of distribution should be described along with. Make improvements to your plan and work with your regulatory authority to ensure your haccp plan is the best it can be. Haccp planning (hazard analysis and.

At the outset, it is pertinent to create a committee of professionals to. Establish a haccp team the haccp team consists of individuals. Principle 1, which is to.

An establishment must still tailor the plan to suit the specific circumstances of its own products and production processes. How to develop a haccp plan. The first task in developing a haccp plan is to assemble a haccp team consisting of individuals who have specific knowledge and expertise appropriate to the product and process.

This team will be in charge of developing the haccp plan in detail, so. The first step to develop a haccp plan is to bring together a multidisciplinary team. The guidance provided on how to develop a haccp plan represents practices that fsis recommends based on scientific and practical considerations.